Durable with high operational reliability

C 5″

C 7,5″

C 10″

C 12,5″

High performance with maximum flexibility.

CR 5″

CR 7,5″

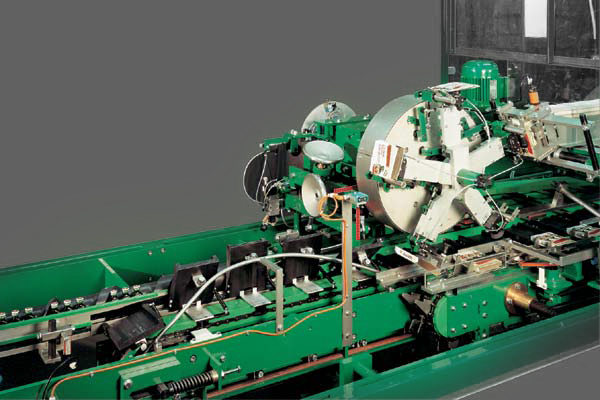

Our continuous motion cartoning machines have proven themselves for over 35 years for cosmetics, pharmaceutical products, luxury beverages, baked goods, chocolates, confectionery, food, technical bulk goods, toys and the like.

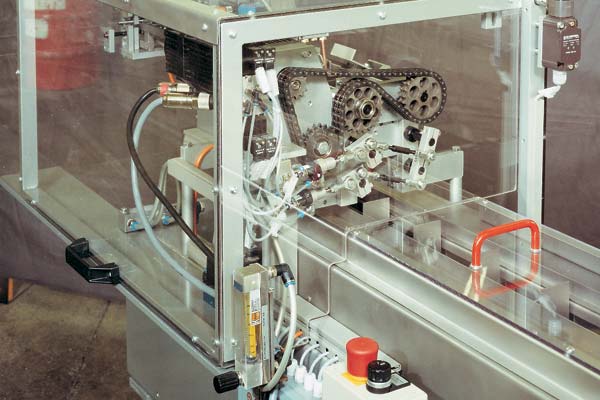

Robust, reliable, easily format-adjustable, low-noise and easy to clean. These are the main requirements of our customers, which we realise.

Our main focus is on product takeovers, as this is where line integration capability is crucial.

Product-specific solutions have proven themselves for:

Vertical infeed bottles in any shape, stand-up pouches, flat pouches, tubular bags, paper stacks, individual paper strips, cellulose articles, trays, thermoformed packs, lamps, relays...

| Technical data (deviations possible) |

||||||

|---|---|---|---|---|---|---|

| Type designation | CF-7,5 | CA-5 | CA7,5 | CA-10 | CK-5 | CK-10 |

| Format length [mm] | 200-350 | 120-250 | 200-300 | 200-400 | 50-200 | 70-20 |

| Format width [mm] | 60-100 | 20-60 | 40-120 | 60-160 | 20-80 | 30-160 |

| Format height | 60-100 | 15-60 | 40-120 | 60-160 | 20-80 | 30-160 |

| Cell pitch | 7,5" | 5" | 7,5" | 10" | 5" | 10" |

| Max output [bottles/min] | 200 | |||||

| Max output [cartons/min] | 250 | 250 | 180 | 160 | 120 | |

In addition to the classic push-in or adhesive closure, there are also devices for centring tabs, additional locking mechanisms for push-in closures, hanging tabs and automatic base closures.

Robust, reliable, easily format-adjustable, low-noise and easy to clean. These are the main requirements of our customers, which we realise.

Our main focus is on product takeovers, as this is where line integration capability is crucial.

Product-specific solutions have proven themselves for:

upright incoming bottles in any shape, stand-up pouches, flat pouches, tubular bags, paper stacks, single paper strips, cellulose articles, trays, thermoformed packs, lamps, relays...

| Technical data (deviations possible) |

||||||

|---|---|---|---|---|---|---|

| Type designation | CR-5 | CR-7,5 | ||||

| Format length [mm] | 50-250 | 100-300 | ||||

| Format width [mm] | 20-80 | 40-120 | ||||

| Format height | 15-40 | 15-40(60) | ||||

| Cell pitch | 5" | 7,5" | ||||

| Max output [bottles/min] | 400 | 400 | ||||

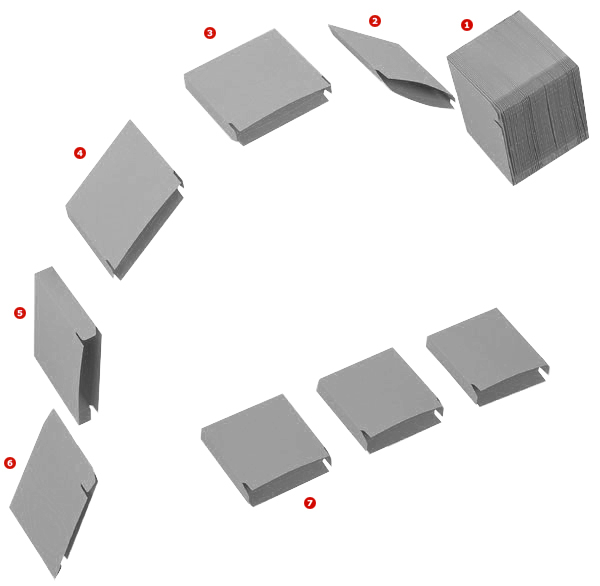

Rotary suction with superimposed rest phase during suction. For folding cartons with approx. 140° pre-break, erection test and ejection.

© 2025 All Rights Reserved.