| Technical data (deviations possible) | |||

|---|---|---|---|

| Type designation | W230 | W350 | W500 |

| Film width | 230 | 350 | 500 |

| Film length Longer film lengths can be realised on customer request | 200 | 600 | 600 |

| Max. pack height The maximum pack height can be increased to 150 mm for W350/W500 on customer request | 80 | 120 | 120 |

| Performance [impacts / min] The maximum pack height can be increased to | 160 | 120 | 100 |

| Film material |

|

||

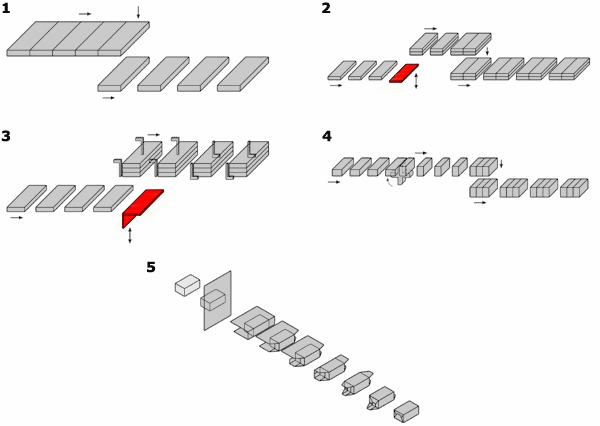

Most mechanical movements are rotary or crank-driven. Where this technology cannot be used, optimally shaped, hardened and polished control cams ensure high performance with a low noise level.

In conjunction with sound-insulating encapsulation, this results in values of less than 78db(A) at high performance.Good accessibility, easy cleaning.

Hardly any maintenance due to encapsulated gears. Consistent installation of permanently lubricated rolling elements for rotary and sliding movements. Split control cams, film take-off, multi-grip grippers, so there are no problems with statically charged films.

Full protection through Makrolon doors in accordance with EN 294.

| Technical data (deviations possible) | |||

|---|---|---|---|

| Type designation | WR200 | WR300 | WR400 |

| Film width | 175 | 250 | 250 |

| Film length Longer film lengths can be realised on customer request | 200 | 300 | 400 |

| Max. pack height The maximum pack height can be increased to 150 mm for W350/W500 on customer request | 40 | 50 | 600 |

| Performance [impacts / min] The maximum pack height can be increased to | 265 | 200 | 185 |

| Min. Folienabzug [mm] | 80 | 80 | 80 |

| Film material |

|

||

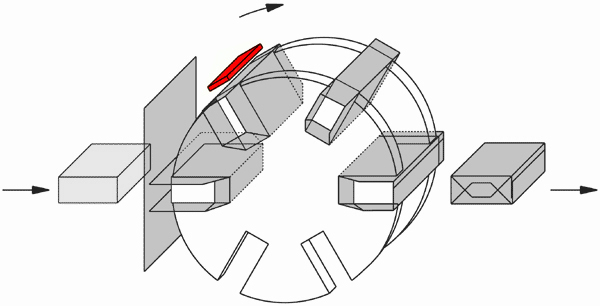

Cellular wheel impact principle.

The product leaves the machine rotated by 180°

© 2025 All Rights Reserved.